Our professional capability is shown through a full range of our products meeting all possible requirements from the bottling industry. From one bottle format unique to automatic change-over for several bottle formats, till universal side guides, from water to carbonated drink, hot-filling, till aseptic filling ,and from one neck guide fix to two automatic change-overs of the neck guide, you can always find a product corresponding to your application at Vaero.

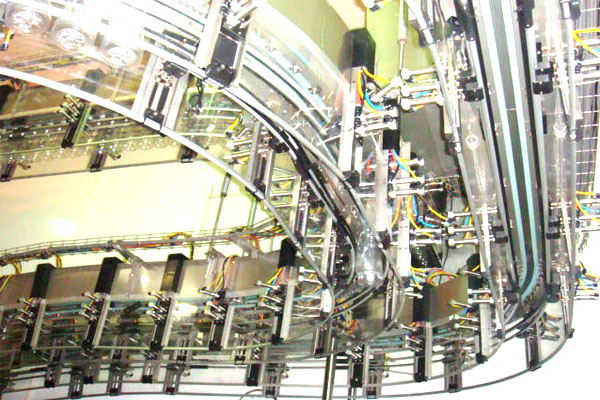

High transport efficiency, good aerodynamic controllability, invulnerability of bottle surface, and easy human-machine interface are the characteristics of Vaero air conveyor systems. Intelligent automatic control serves to save electric energy and ensure the best transport performance of bottles. Human-machine interface is English-Chinese bilingual which can be easier for different users.

No matter how many bottle formats you produce on one same line, Vaero has a product for you. From one bottle format unique to automatic change-over for several bottle formats, till universal side guides (Patent :ZL200720127986.4), Vaero has a complete range covering all your requirements on the number of bottle formats that you want to transport on one line.

No matter what kind of drinks you produce, you can have a product from Vaero. Vaero have different solution for water, carbonated drinks, hot-filling drinks and aseptic filling drinks.

Two neck guide sizes--you need just several seconds to finish this chang-over on the same line on Vaero’s line.

Different bottling speeds—Vaero also has different designs for different bottling speeds. The highest speed Vaero has served in 72,000 BPH for Nestle.